Leading glass manufacturer Beatson Clark has invested almost £3 million in the latest upgrade at its South Yorkshire glassworks.

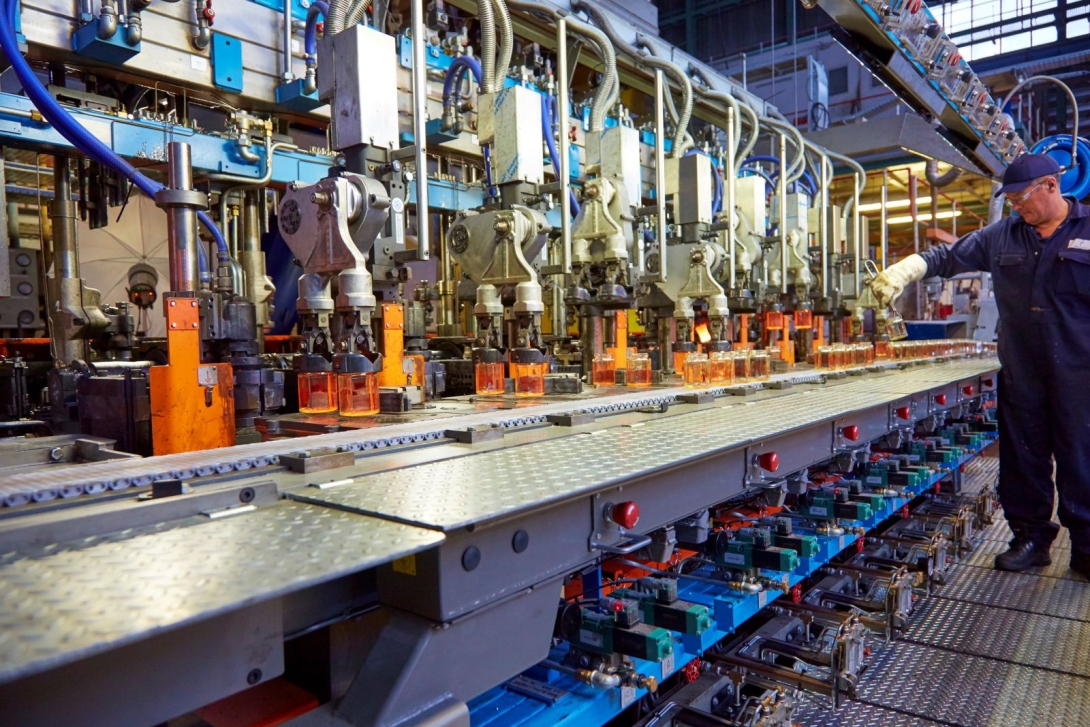

The company has installed Bottero individual section (IS) machines on two of its manufacturing lines to improve production of glass bottles.

The IS machines form glass containers for well known food brands such as English Provender and Mackays, as well as major UK retailers’ own brand products like spice jars.

Individual gobs of molten glass are fed into the machines where they are formed into finished containers. The two machines operate 24/7 and produce on average 160 million white flint bottles and jars each year.

Graham Lax, head of project management at Beatson Clark said:

“These new eight-section double gob machines represent the latest generation in servo controlled equipment.

“This investment is part of our commitment to continuous improvement for the future and will ensure that we can improve our production processes while maintaining and enhancing quality.”

The new machines were installed by ECO Engineering of Brough in East Yorkshire while machine and mould cooling fans were installed by Integrated Air Systems Ltd.

Notes

Beatson Clark specialises in providing glass packaging solutions for niche brands in the food, drink and pharmaceutical markets worldwide.

The key to its success has been flexibility, innovation and the high quality of its containers. It has has a turnover of £48 million and a production capacity of approximately 520 million units or 145,000 tonnes.

It employs approximately 330 people. It has ISO 9001:2008, BRC/IOP Food Packaging Hygiene Standard and OHSAS 18001:1999 Occupational Health & Safety Standard and its manufacturing capability has an emphasis on flexibility to facilitate short tailored production runs.

It's UK distribution centre located in Rotherham. To find out more visit www.beatsonclark.co.uk